Pavement sinkholes like the massive one recently at Flemington Road & Abbotsford Street in North Melbourne are among the most dramatic failures in road infrastructure. They can appear suddenly, cause huge disruption, and pose serious safety risks for pedestrians and vehicles.

In this blog post, we’ll explain what typically causes these sinkholes beneath asphalt pavements, and how they can be effectively remedied, drawing on our own recent experience fixing the North Melbourne case, as well as accepted civil engineering practices.

What Causes Pavement Sinkholes Under Asphalt Roads?

Although sinkhole often evokes images of underground caves collapsing, pavement sinkholes usually result from a mix of structural, soil, and water-infiltration problems not just geology. Common causes include:

- Water Infiltration and Leaking Underground Services

Cracked storm-water drains, leaking water mains, or damaged sewer pipes can seep water into the sub-base beneath the road. With time, this water washes away soil or base-aggregate, creating voids. Once there’s insufficient support under the asphalt, the surface collapses hence a sinkhole.

In many urban sinkholes (like the one on Collins Street in Melbourne’s CBD), investigation revealed that a cracked drain pipe triggered the collapse. - Poor Sub-Base Construction and Inadequate Compaction

If when the road was originally built the sub-base was not properly compacted, or if low quality materials were used, the pavement may gradually settle under load especially under vehicle traffic, causing depressions that may worsen over time. - Soil Erosion After Heavy Rainfall or Water Leakage

In areas where rainfall, runoff, or groundwater is poorly drained, water can erode fine soil particles or shift base materials — undermining support for the asphalt above. Over time, that leads to subsidence and collapse. - Heavy Vehicle Loading and Pavement Fatigue

Roads that endure heavy loads (e.g. delivery trucks, buses) repeatedly stress the pavement and its base. If the base is already compromised, repeated load cycles accelerate failure, leading first to cracking (e.g. “fatigue cracking” or “crocodile cracking”), then potholes or sinkholes. - Aging asphalt and oxidation

Over time, the asphalt binder degrades (especially under UV exposure), making the surface brittle and more prone to cracking. Once cracks form, water can seep in and start the erosion of the base below.

How to Repair — Best Practices & Our Recent Approach

When a serious sinkhole appears, a robust, multi-layered fix is needed not a quick cold patch. Based on our recent work at Flemington Rd/Abbotsford St, and accepted industry methods, the following represents a sound repair approach.

Recommended 6 Steps for Permanent Sinkhole Repair

Step 1: Isolate and assess the underlying cause

Before any asphalt repairs, investigate for utility leaks (water, gas, sewer, drainage). If pipes or mains are damaged, repair those first. In urban settings this is critical. (In our recent fix, we ensured utility services gas, water, sewer mains were all repaired before reinstating the pavement.)

Step 2: Excavate to remove unstable or contaminated material

Remove all failed pavement, loose soil, saturated sand, debris basically anything that contributed to void formation. Ensure you dig down to stable soil or load-bearing base.

Step 3: Rebuild the base / sub-base in compacted layers

- Place a first layer of stabilized sand to provide drainage and bedding.

- Over that, add crushed rock (aggregate base) grain-size graded aggregate base (GAB) in layers, compacting each layer thoroughly.

- In many cases, alternate with additional sand layers (or a combination of sand + engineered fill) to enhance drainage and support.

- For large voids or deep sinkholes, consider using cellular concrete (flowable fill) or grout injection as a light but stable fill to support loads.

Step 4: Compact every layer properly

Proper compaction is non-negotiable. Without good compaction, the base can settle over time leading to future failure. For our repair, we compacted at every stage: after sand, after crushed rock, after final stabilised sand, and then after laying asphalt.

Step 5: Lay and compact the asphalt surface (hot-mix if possible)

Use a hot-mix asphalt (or equivalent high-quality mix), ensure proper tack coat or binder between layers, then compact with a vibratory roller. If conditions don’t allow hot mix, a semi-permanent “hot-patch” method is preferred over cold-patch.

The surface should be finished with a slight crown or camber to ensure water runs off, not pools which helps prevent water infiltration in the future.

Step 6: Ensure drainage and monitor over time

Once repaired, ensure drains, storm-water systems, and surrounding drainage direct water away from the repaired area. Consider periodic inspections — especially after heavy rain — to spot early signs of subsidence or cracking.

Our Recent Repair — Flemington Rd & Abbotsford St, North Melbourne

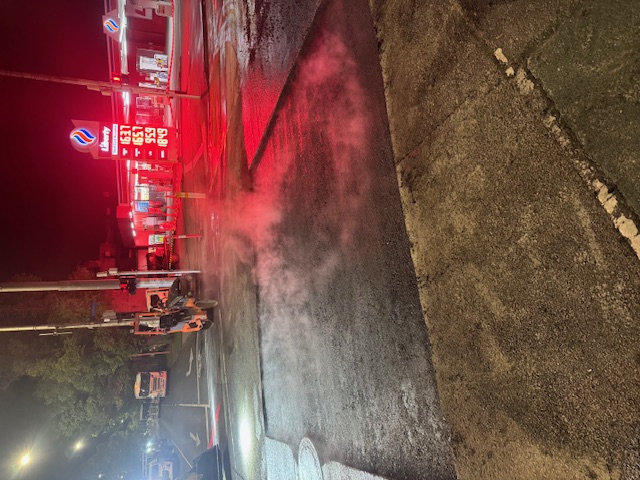

In inner Melbourne suburbs, ageing drainage infrastructure combined with heavy bus and tram traffic significantly increases sinkhole risk. At the Flemington Rd & Abbotsford St in North Melbourne, the sinkhole was significant large enough that media and passers-by said you could “fit a whole car in it.”

Our team carried out the following proven repair sequence:

- First, fixed underlying utility services (gas, water, sewer mains) to remove root cause risk.

- Excavated and cleaned out all unstable or void-forming material.

- Laid a stabilised sand bedding, compacted.

- Backfilled with crushed rock aggregate base (GAB), compacting in layers.

- Added a second stabilised sand layer for bedding/cushion.

- Finally, laid a new asphalt surface and compacted using a vibratory roller, ensuring proper bonding and smooth finish.

This method provided a strong, stable base not just a patch. It significantly reduces likelihood of recurrence especially if drainage is functioning well and loads remain within design capacity.

Why “Quick-Fix” Methods Often Fail

Some common pothole-repair methods cold-patch, spray-injection, “throw-and-roll” are temporary solutions at best. They may fill the visible hole, but do not address the voids or weakened base below. Over time, traffic stress and water infiltration often cause failure again.

Even filling a driveway sinkhole with gravel or sand (without proper compaction/engineering) often results in more subsidence.

For major sinkholes under public roads especially intersections a full structural repair (as outlined above) is the responsible, long-lasting solution.

Prevention & Maintenance — How to Reduce Risk of Sinkholes

Prevention is always better than dealing with a catastrophic collapse. Some effective strategies:

- Regular inspection of underground utilities and drainage systems. Leaks should be addressed before they undermine the base.

- Ensure proper drainage & surface water runoff — roads should be graded and drains maintained to avoid water pooling or infiltration.

- Use the correct base design and compaction when resurfacing or building roads. Never skip base preparation or compaction.

- Use high-quality asphalt and surface treatments to resist cracking and water penetration. Regular maintenance (seal-coating, crack sealing) helps extend lifespan.

- Monitor heavily trafficked or historically problematic areas for early signs of subsidence or cracking.

Conclusion — Why Proper Sinkhole Repair Matters

Sinkholes under paved roads are rarely just surface problems they signal deeper structural, drainage, or sub-base failures. While quick asphalt patches might restore usability temporarily, only a proper, layered repair addressing utilities, sub-base stabilisation, drainage, and asphalt paving delivers a long-term solution.

Our recent project at Flemington Rd & Abbotsford St demonstrates how doing things by the book even when it’s more labour-intensive delivers a durable, safe road surface for the public.

If your organisation or municipality wants to showcase professional, long-lasting road repairs and avoid recurrent failures this layered, engineered approach is the way to go.

Frequently Asked Questions About Pavement Sinkholes

What causes sinkholes under asphalt roads?

Pavement sinkholes are usually caused by a combination of water infiltration, poor sub-base construction, soil erosion, heavy traffic loading, and ageing asphalt. Leaking underground utilities such as stormwater drains, water mains, or sewer pipes can wash away supporting material beneath the road, creating voids that eventually lead to surface collapse.

Are pavement sinkholes the same as natural sinkholes?

No. While natural sinkholes are often caused by geological processes such as underground cave collapse, pavement sinkholes typically result from infrastructure-related issues. These include compromised drainage systems, inadequate compaction during construction, and long-term erosion of the road’s sub-base rather than natural geology alone.

Why does water infiltration play such a major role in pavement sinkholes?

Water infiltration weakens the pavement structure by washing away soil or base materials beneath the asphalt. Once voids form and the base loses support, the asphalt surface can no longer carry traffic loads, leading to cracking, subsidence, or sudden collapse.

How does poor sub-base construction contribute to sinkhole formation?

If the sub-base was not properly compacted or constructed with suitable materials, it can gradually settle under traffic loads. Over time, this settlement can create depressions and voids beneath the pavement surface, increasing the risk of sinkholes forming.

Why do quick-fix repairs like cold patching often fail?

Quick-fix methods typically address only the visible surface damage. They do not repair the underlying voids, unstable soil, or drainage issues that caused the sinkhole. As a result, traffic loads and water infiltration often lead to repeat failure in the same location.

What is the correct way to permanently repair a pavement sinkhole?

A permanent repair requires identifying and fixing the underlying cause, removing all unstable material, rebuilding the base and sub-base in compacted layers, and reinstating the asphalt surface using proper compaction techniques. Drainage must also be addressed to prevent water from re-entering the repaired area.

Why is proper compaction critical during sinkhole repairs?

Proper compaction ensures that each layer of sand, aggregate, and asphalt can support traffic loads without settling. Inadequate compaction can allow the repaired area to sink over time, leading to cracks, depressions, or renewed collapse.

How can pavement sinkholes be prevented in the future?

Preventative measures include regular inspection of underground utilities, maintaining effective drainage systems, using correct base materials and compaction methods during construction, and performing routine asphalt maintenance such as crack sealing to limit water penetration.